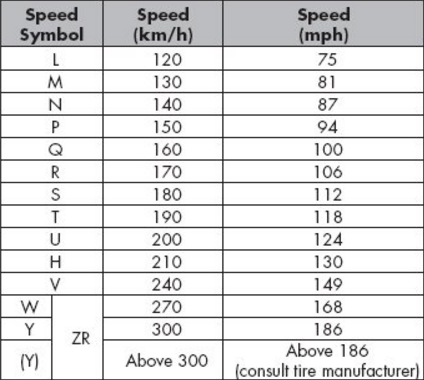

The speed rating of a tyre indicates the speed category (or range of speeds) at which the tyre can carry a load under specified service conditions. The speed rating system used today was developed in Europe in response to the need to categorize tyres into standardized speeds. A letter from A to Z symbolizes a tyre's certified speed rating, ranging from 5km/h (3 mph) to above 300 km/h (186 mph).

P-metric sized tyres are those with the "P" at the

beginning of the tyre size (such as P215/65R16). P-metric sizes were introduced

in the United States in the late 70s and are installed on vehicles primarily

used to carry passengers, including cars, estate cars, sport utility vehicles

and even light-duty pick-up vans. Their load capacity is based on an

engineering formula which takes into account their physical size (the volume of

space for air inside the tyre) and the amount of air pressure (how tightly the

air molecules are compressed). Since all P-metric sizes are all based on the

formula for load, vehicle manufacturers can design their new vehicles (weights

and wheel well dimensions) around either existing or new tyre sizes.

Metric or Euro-metric sized tyres are the ones

without the ""P"" at the beginning, (such as 215/65R16).

Using metric dimensions to reflect a tyre's width actually began in Europe in

the late 60s. However, since Euro-metric sizes have been added over time based

on the load and dimensional requirements of new vehicles, tyre manufacturers

have designed many new tyre sizes and load capacities around the needs of new

vehicles. Not quite as uniform as creating sizes using a formula, but they got

the job done.

Euro-metric and P-metric tyres in the same size

(i.e. P215/65R16 and 215/65R16) are equivalent in their dimensions with just

slight differences in their load-capacity calculations and inflation-pressure

tables.

The side of a tyre contains information

needed for your safety and that of your customer. Being able to read sidewall

markings will help you to better understand the performance of each tyre. It

will also provide you with information when mounting and servicing the tyre.

Passenger Tyre Sizing

Three primary sizing systems exist for

passenger tyres today: P-Metric, European Metric and Millimetric. Each of these

systems evolved from the first tyre sizing system – the Numeric Sizing system –

that is now obsolete. It was developed when all tyres had the same aspect

ratio, and it provided only the nominal cross-section width of the tyre and the

rim diameter in inches. The following are examples that identify the three sizing

systems that are commonly seen today.

P-Metric

The P-Metric sizing system was developed

to better align with the European tyre-sizing system. It provides a better

description of the tyre size. See examples below. · Passenger Car Tyre · Section width in Millimeters · Aspect Ratio · Speed Rating · Radial Construction · Rim Diameter in Inches · Service Description (Load Index and Speed Rating)

European Metric

Essentially, this system was a

conversion of the Numeric system from inches to millimetres. Aspect ratio

appears in the size designation in most cases where it is other than 82.

Light Commercial Vehicle Sizing

Sizing for light commercial vehicle

tyres takes the performance requirements of the vehicle, and the tyres, into

account. Light commercial vehicle tyres have evolved along with the expanded

applications of lorries and vans that have grown to be multi-purpose vehicles

that we use for work, for recreation or as passenger vehicles. There are three

primary light commercial vehicle tyre-sizing systems: Light Commercial Vehicle

Metric, Light Commercial Vehicle High Floatation and Light Commercial Vehicle

Numeric.

Light Commercial Vehicle Metric

This sizing system mirrors the P-Metric

system for passenger tyres.

Light Commercial Vehicle Designation · Tyre Overall Diameter in Inches · Section width in Millimeters · Section width in Inches · Aspect Ratio · Radial Construction · Rim Diameter in Inches · Load Range · Light Commercial Vehicle High Flotation

Light commercial vehicle high-flotation

tyres have evolved as lower aspect ratio tyres became more popular on light

commercial vehicles. The combination of lower aspect ratios and high flotation

yielded better traction on the sand and soft soil found in off-road situations.

A tyre is mounted on the appropriate rim width as identified by T&RA (Tyre &Rim Association) or ETRTO (European Technical Rim & Tyre Organization) then inflated to 1.8 bar (26 psi). A calibrated measurement tape is run around the circumference of the tyre in the center of the tread (which represents the largest overall diameter). This measurement of circumference is then divided by the mathematical constant known as PI (3.14126...) to calculate the diameter.

The rim width range is extremely important. This range

represents proper rim widths that will assist the tyre/wheel assembly in

meeting its performance potential. To achieve the best balance between ride,

handling and tread wear, select a rim width in the middle of the manufacturer’s

range.

To improve cornering traction and steering

response, choose a rim at or near the maximum recommended width. The wider the

rim width, the straighter the sidewall and the quicker the steering response.

Conversely, using a rim width at the low end of the range will cause the tyre

to balloon or curve out, slowing steering response.

Refer to our website for tyre specifications.

Never exceed the load-carrying limits moulded on the sidewall of the tyres or the maximum vehicle axle load limit as shown on the vehicle tyre placard, whichever is less. Overloading builds up excessive heat in the tyre and could lead to failure.

If no instructions for tyre mixing

appear in the vehicle owner’s manual, adhere to the following guidelines: · Do not mix sizes. All four tyres must be branded with the

same tyre size. · Do not mix radial and non-radial tyres. All four tyres

must be either radial or non-radial. · Ensure that the outside circumference of all four tyres

is within 2.5 cm (one (1) inch) of each other.

Tyres with directional tread patterns must be

mounted so that the primary direction of rotation matches the directional

arrows on the tyre sidewall. If all four tyres are the same size, directional

tyres can be rotated front to back.

Tyres with tread patterns that are both

asymmetric and directional require left and right specific tyres. Sidewall

markings will identify the side of the vehicle and the primary direction of

rotation for the tyre. If all four tyres are the same size, they can be rotated

front to back.

Never try to mount your own tyres. Tyre mounting is a job for people who have the proper equipment and experience. If you try to do it yourself, you run the risk of serious injury to yourself as well as possible damage to the tyre and rim.

We recommend using a soft brush and mild soap to clean tyres. Tyre dressings that contain petroleum products or alcohol can accelerate the ageing process and contribute to cracking.

ALTAIRE does not endorse the use of after-market conditioners. The effects of such products are unknown as it would be impossible to test all of the products on the market today.

Yes. Here are several tips to help increase the life of your tyres:

Don’t speed. High speeds can generate excessive heat, which can increase the rate of tyre wear. Drive at the safe, legal speed limit.

· Avoid fast turns on curves and around corners.

· Avoid fast starts and panic stops.

Don’t ride on the edge of the road or drive over kerbs, potholes or other obstructions.

Special treatment is not required for your new tyres. However, drive carefully while you get accustomed to them. You may feel a difference when accelerating, braking, cornering or possibly driving in wet conditions.

We cannot test all products being marketed today, and do not certify or endorse any of these after-market products for efficiency or compatibility.

Because some of these products may degrade the inner liner of tyres, caution should be taken. The long-term effect of these products is unknown (chemical reaction when exposed to pressure, temperature and time).

Because some of these products may be flammable, we strongly urge you to advise a tyre dealer of the use of these products before having the tyre and wheel serviced. Failure to do so could lead to serious injury or death.

Please refer to the warnings and instructions provided by the manufacturers of these products regarding their use.

We neither approve nor disapprove the use of these products.

Each tyre has a required Department of Transportation (DOT) number imprinted on at least one of its sidewalls. That number begins with the letters "DOT" and may contain up to 12 additional numbers and letters.

The first and last digits are the most important:

· The first two letters or numbers identify the tyre’s manufacturer and plant code.

· Prior to the year 2000, the last 3 digits of a DOT number represented the week (2 digits) and the year (1 digit) of production. So if the last three digits are 439, the tyre was produced in the 43rd week of 1999.

· Tyres produced after 1 January 2000, have a 4-digit date code at the end of the DOT number. The first 2 digits represent the week of production and the last 2 digits represent the last 2 digits of the year of production. So, 3500 indicates that the tyre was produced in the 35th week of the year 2000.

Although bar-code label removal is not necessary for

the safe and efficient use of the tyre, it may be necessary to remove the label

for aesthetic reasons. The 16 mm by 40 mm bar-code label on the lower sidewall

may be difficult to remove from some tyres. Please advise your tyre dealer that

label removal may be facilitated by applying with a cotton swab a small amount

of paint thinner (mineral spirits) to the label on a MOUNTED, INFLATED tyre.

Then, carefully pry under the centre of the label with a flat-bladed

screwdriver to remove it. Your dealer will do this slowly and carefully to

avoid damaging the tyre. After the label has been removed by this procedure,

the tyre should be carefully inspected.

We are currently perfecting a more readily removable bar-code label. In the meantime, the above procedure provides an effective method of removing the occasional "stubborn" bar-code label from the tyres when necessary.

Properly maintained tyres can help to give you a more comfortable ride and a longer tread life. So:

· Check your tyre pressure monthly with a tyre-pressure gauge (and make sure that the tyres are cold – at least 3 hours after driving).

· Check your tyres frequently for any cuts, snags, punctures, any other injury, or irregular tyre wear.

· At the first sign of irregular tread-wear, have your alignment checked.

· Make sure that the tyres are balanced when they are mounted on the wheels.

· Rotate your tyres following the schedule in your vehicle owner’s manual or as required by the tyre manufacturer’s warranty.

We do not offer a written mileage warranty on any tyres supplied as original equipment. Due to the variety of styles, construction features, tread compounds, vehicle applications, geographical conditions and driving habits, it is difficult to provide a specific mileage expectancy.

However, any tyre-wear concern should always be presented to your local authorized dealers for further evaluation.

Many of our authorized retailers offer specific mileage warranties on several lines of tyres sold as replacement tyres, including some tyres that are used as original equipment. These mileage warranties are administered based on the retail outlet's verification of proper tyre maintenance having been performed.

Many factors can affect the tread life of your tyres, such as:

· Tread compounds

· Construction features

· Vehicle application

· Tyre maintenance

· Geographic conditions

· Atmospheric conditions

· Driving habits

· And more

That’s why exact mileage is impossible to predict. Take special care when braking, accelerating and cornering, etc., to help increase the life of the tyre. (Owning tyres with ALTAIRE’s technology doesn’t hurt either.) If you have concerns about the rate of wear on your tyres, consult your local authorized ALTAIRE retailer.

Tyres should be stored in a cool place away from direct sunlight, sources of heat and ozone such as hot pipes and electric generators. Exposure to these elements during prolonged periods of time will exhaust the tyre's oxidation and weathering agents within the rubber compounds and result in cracking. Be sure that the surfaces on which the tyres are stored are clean and free from grease, fuel or other substances that could deteriorate the rubber.

For mounted tyres inflate at, but no higher than, the recommended air pressure. Store vehicles on blocks to remove the load from the tyres.

If a tyre loses all or most of its air pressure, it must be removed from the wheel for a complete internal inspection to be sure that it's not damaged. Tyres that are run for even short distances while flat are often damaged beyond repair. Most punctures, nail holes, or cuts of up to 0.6 cm (1/4 inch) - – confined to the tread - – may be satisfactorily repaired by trained personnel using industry-approved methods. Don't repair tyres with tread punctures of larger than 0.6 cm (1/4 inch), or any sidewall puncture. Also, never repair tyres which are worn below 1/16-inch tread depth. Your best bet is to make sure that your spare tyre is always ready to do the job. Check it regularly for proper air pressure and be sure that it is in good shape. If your car is equipped with one of the several types of temporary spares, be sure to check the spare tyre's sidewall for the correct inflation pressure, speed and mileage limitations. See your dealer for expert tyre repair.

New tyres have to be driven for a few hundred miles on dry roads to rid the tread of the parting agents and antioxidants applied during production. Not until the tread has been slightly roughened will the tyre be able to make its true gripping power felt.

Tread-wear indicators ("wear bars") are located at the base of the main grooves and are equally spaced around the tyre. The tread-wear indicators, which look like narrow strips of smooth rubber across the tread, will appear on the tyre when that point of wear is reached. When you see these wear bars, the tyre is worn out and it is time to replace the tyre. Always remove tyres from service when they reach a remaining tread depth of two thirty-seconds of an inch (2/32"). Another easy way to check is to do the 20 pence test. Take a 20 pence piece and place it in the tread groove. If you can see some of the out edge of the coin, then it is time to replace your tyres.

Never choose a smaller size than those that came with the car. Tyres should always be replaced with the same size designation - – or approved options – as recommended by the vehicle manufacturer or authorized dealer.

Proper balancing is critical for optimal vehicle performance, especially at today's higher motorway speeds. When tyre and wheel assemblies are unbalanced, a vibration can result from wheel and assembly shimmy (shaking from side to side) or wheel assembly tramp (tyre and wheel hopping up and down). Therefore, it is important that these assemblies are in both static and dynamic balance.

When installing a different size than the original equipment tyre, all vehicle manufacturer specifications must be maintained. The replacement tyre should be inflated to provide the same load capability of the original tyre size at the manufacturer’s recommended pressure.

Please contact one of our Consumer Care agents to determine the correct pressure for the optional tyre size that you are installing or visit your local tyre retailer for assistance.

A vehicle is said to be properly aligned when all suspension and steering components are sound and when the tyre and wheel assemblies are running straight and true. Proper alignment is necessary for even tread wear and precise steering. Uneven front or rear tyre wear, or changes in your vehicle's handling or steering response (i.e. pulling to one side) can indicate misalignment. Many vehicles today are equipped with rear suspensions that can be adjusted for alignment. Your vehicle many need a "front-end" alignment or a "four-wheel" alignment, depending on the symptoms you are experiencing. The moderate cost of having your vehicle aligned can more than pay for itself in tyre mileage, performance and comfort.

The vehicle manufacturer selects the size and type of tyres for their vehicles. They perform the necessary testing to establish the vehicles’ optimized operating tyre inflation pressures which can be found on the vehicle placard (located on the inside of the driver's door) and in the vehicle owners’ manual.

If the tyres on your vehicle are the same size as the original equipment tyre, inflate them to the pressures indicated on the placard.

If the size of the tyres is different than the size indicated on the placard, please contact us via phone or e-mail for a pressure recommendation. We will need the following information from the tyre and wheel placard:

– the original equipment tyre size

– the vehicle manufacturer's inflation pressure.

While most tyres will need replacement before they achieve 10 years, it is recommended that any tyres in service for 10 years or more from the date of manufacture, including spare tyres, be replaced with new tyres as a simple precaution even if such tyres appear serviceable and even if they have not reached the legal wear limit.

Lower inflation pressures for improved flotation are permitted ONLY if the tyre maintains adequate load-carrying capacity at the lower pressure. 20 psi is the minimum recommended pressure for a passenger or light commercial vehicle tyre. Pressures lower than 20 psi may be used off-road when speeds are less than 15 mph and when the tyre has adequate load-carrying capacity at the lower pressure.

The best recommendation for motorway use is to follow the inflation pressure specified by the vehicle manufacturer which can be found in the owner’s manual or on the sticker on the inside of the driver’s door.

When installing a different size than the original equipment tyre, the replacement tyre should be inflated to provide the same load capability of the original tyre size at the manufacturer’s recommended pressure.

Nitrogen is an inert gas. It is simply dry air with the oxygen removed (air contains nearly 79% Nitrogen). The physical properties of nitrogen reduce the pressure loss due to the natural permeability of the materials of the tyre. Unfortunately, there are other possible sources of leaks (tyre/rim interface, valve, valve/rim interface and the wheel) which prevent the guarantee of pressure maintenance for individuals using air or nitrogen inflation. Tyres manufactured by Michelin are designed to deliver their expected performance when inflated with air or nitrogen, as long as the user respects the pressures recommended by the vehicle manufacturer on the vehicle's placard or those of the tyre manufacturer. Whether they are inflated with air or nitrogen, regular pressure maintenance remains critical because under-inflated tyres lead to:

a reduction in road holding

a reduction in wet traction capability

an increased sensitivity to road hazards

a reduction in tread-life

an increase in fuel consumption

a reduction in tyre life due to excessive heat from over deflection

In addition to performing regular maintenance, you

must also keep an eye out for potential problems that might affect your tyres.

Regular inspections can help you prevent tyre trouble, and keep you rolling

safely down the road.

When inspecting your tyres, look for:

Uneven tread wear: This can include more wear on one tread edge than the other, a rippled pattern of high and low wear, or exposed steel wire. Uneven wear can be caused by problems such as under-inflation, misalignment and improper balancing.

Shallow tread: Bald tyres tend to skid and slide on the road, and are more likely to be damaged by potholes and other road hazards. The tread on your tyre should be at least 1.58 mm (1/16 of an inch) deep. If it isn’t, the tyre must be replaced. To help you see tread problems, tyres have built-in “tread-wear indicators”. These are narrow bars of smooth rubber that run across the tread: When the tread is even with the bars, it is worn down to the minimum level and must be replaced immediately.

You can also perform a simple test using a 20 pence piece. Put the edge of the coin into the tread. If you cannot see the rim that’s good. If you can see some of the rim, it’s time to replace the tyre.

Troublemakers. Check for small stones, pieces of glass, bits of metal and other foreign objects that might be wedged into the tread, and carefully pick them out. They can cause serious problems if they are pushed further into your tyre as you drive.

Damaged areas. Cracks, cuts, splits, punctures, holes and

bulges in the tread or on the sides of the tyre can indicate serious problems,

and the tyre may need to be replaced.

Slow leaks. Tyres lose some air pressure (about 2 psi) over the course of a

month or so, but if you find that you have to add air every few days, have the

tyre, wheel and valve checked – and if necessary, repair or replace the tyre.

Valve caps. Those little caps on your tyre’s valve stem keep moisture and dirt out, so make sure they are on all your tyres. Also, when you have a tyre replaced, have a new valve stem assembly installed at the same time.

Driving on a damaged tyre can be dangerous. If you see

something that you’re not sure about during your inspection, have it examined

by your tyre dealer. Any time that you see damage to a tyre, don’t drive on it

– use a spare if you need to go somewhere. And finally, pay attention to the

“feel” of your tyres as you drive. A rough ride may indicate tyre damage or

excessive wear. If you notice vibrations or other disturbances while driving,

and/or you suspect possible damage to your tyre or vehicle, immediately reduce

speed, drive with caution until you can safely pull off the road and stop, and

inspect your tyres. If a tyre is damaged, deflate it and replace it with your

spare. If you do not see any tyre damage and cannot identify the source of the

vibration, take the vehicle to a tyre dealer for a thorough inspection.

Air pressure in tyres, including the spare, should be checked at least monthly and always before extended driving. Tyres should be checked when they are cold (at least three hours after the vehicle has been stopped and before it is driven more than one mile or two kilometers). Do not reduce pressure when tyres are hot; use an accurate air-pressure gauge to check pressure and maintain it at the level recommended on the vehicle tyre vehicle placard or in the vehicle owner’s manual. Under-inflation produces extreme flexing of the tyre and builds up heat to the point that tyre failure may occur. Over- or under-inflation may adversely affect vehicle handling. Cold tyre pressures should never be higher than the limit moulded on the sidewall.

While most tyres will need replacement before they achieve 10 years, it is recommended that any tyres in service for 10 years or more from the date of manufacture, including spare tyres, be replaced with new tyres as a simple precaution even if such tyres appear serviceable and even if they have not reached the legal wear limit.

For tyres that were on an original equipment vehicle (i.e. acquired by the consumer on a new vehicle), follow the vehicle manufacturer’s tyre replacement recommendations, when specified (but not to exceed 10 years).

The date when a tyre was manufactured is located on the sidewall of each tyre. Consumers should locate the Department of Transportation or DOT code on the tyre which begins with DOT and ends with the week and year of manufacture. For example, a DOT code ending with “2204” indicates a tyre made in the 22nd week (May) of 2004.

Worn tyres should be replaced by trained personnel when 1.58 mm (2/32nds of an inch) of tread depth remains, as indicated by tread-wear indicators moulded into the tread grooves. Use of worn out tyres [less than 2/32nds inch (1.58 mm) remaining of tyre tread depth] increases the probability of tyre failure, and in wet conditions can cause the tyre to lose traction suddenly. In most states, it is illegal to drive with less than 1.58 mm (2/32nds of an inch) of remaining tread depth.

ALTAIRE recommends replacing all four tyres at the same time, however if replacing only two new tyres, be sure that the new tyres are the same size & tyre type as the current tyres and that the dealer always installs the new tyres on the rear axle of the vehicle

· The New tyres will provide better wet grip than your half-worn tyres.

· It will help to reduce the potential for the vehicle to fish-tail and lose stability in wet conditions

The tyre size and tread design that was originally equipped on your vehicle may be used on other vehicles, some of which being heavier than others, therefore requiring higher air pressure for additional load-carrying capacity.

The maximum pressure on the sidewall of the tyre is the maximum pressure for the tyre. The manufacturer of the vehicle has determined the appropriate air pressure for the application based on vehicle weight, to provide the best ride, tread wear, performance, etc. For applications such as towing, pulling and hauling, etc., air pressure should be increased accordingly.

Never try to mount your own tyres. Tyre mounting is a job for people who have the proper equipment and experience. If you try to do it yourself, you run the risk of serious injury to yourself as well as possible damage to the tyre and rim.

If tyres of different speed ratings are mounted on a vehicle, the lower speed-rated tyres should be placed on the front axle. This is to prevent a potential over-steer condition. Vehicle handling may be affected, and the vehicle’s speed capacity is now limited to the lowest speed-rated tyre.

For the best all-around performance, the same type of tyre should be used on all four wheel positions. Tyres of different size designations, constructions and stages of wear may affect vehicle handling and stability. NOTE: Some vehicles are intentionally fitted with different size tyres on the front and rear.

For four-wheel drive vehicles, if no instructions for tyre mixing appear in the vehicle owner’s manual, adhere to the following guidelines:

· Do not mix sizes. All four tyres must be branded with the same tyre size.

· Do not mix radial and bias-ply tyres. All four must be either radial or bias-ply.

· Ensure that the outside circumference of all four tyres is within 2.5 cm (1”) of each other

· Do not mix tread patterns, such as all-terrain and all-season.

When replacing speed-rated tyres, you must use replacement tyres with ratings equal to or greater than those of the original equipment tyres, if the speed capability of the vehicle is to be maintained. The handling of a performance vehicle may be different when the replacement tyres are not the same speed rating. Refer to the vehicle owner’s manual to identify any tyre speed-rating restriction that could affect the operation of the vehicle.

Never choose a tyre that is smaller in size or has less load-carrying capacity than the tyre that came with the vehicle. Tyres should always be replaced with the same size designation – or approved options – as recommended by the vehicle or tyre manufacturer. The correct tyre size can be found on the door placard of the vehicle or by consulting your local authorized ALTAIRE retailer. Your current tyre's size can be found by reading the markings on the sidewall.

All new ALTAIRE tyres purchased after 1 January, 2016, are backed by the ALTAIRE Promise Plan, which includes a Satisfaction Guarantee, Flat Tyre Changing Assistance and a Limited Mileage Warranty. Take the tyre to your local authorised ALTAIRE dealer and have them properly inspect the tyre. Tell the dealer what you are experiencing so they can diagnose the problem.

ALTAIRE recommends replacing all four tyres at the same time, however if replacing only two new tyres, be sure that the new tyres are the same size & tyre type as the current tyres and that the dealer always installs the new tyres on the rear axle of the vehicle.

The New tyres will provide better wet grip than your half-worn tyres. It will help to reduce the potential for the vehicle to fishtail and lose stability in wet conditions

When the center tread wears faster than the adjacent tread surfaces, possible causes include over inflation for load carried, rim width too narrow, misapplication, smooth wear after spin-out, improper tyre rotation practices, aggressive acceleration or under-inflation for certain tyre types, such as performance tyres.

If the tread depth is at or below 1.58 mm (2/32") in any groove or if cord material or under tread is exposed, the tyre must be replaced. If sufficient tread remains, verify the proper rim width and vehicle fitment as well as verifying/adjusting inflation pressures, then rotate the tyres for maximum wear.

When the shoulder of the tread on one side of a tyre wears faster than the adjacent tread surface, this can result from a variety of conditions, such as front and/or rear misalignment (example, toe or camber), loose or worn suspension components, hard cornering, improper tyre-rotation practices, misapplication, high crown roads or non-uniform mounting.

If the tread depth is at or below 1.58 mm (2/32") in any groove or if either cord or under tread is exposed, the tyre must be replaced. If sufficient tread remains, verify that the tyre has been properly mounted, then rotate the tyres for maximum wear.

When tread is worn in one or more spots around the tyre circumference, this can indicate brake lock/skid, improper balance, localized underlying separation, loose/worn suspension components, improper bead seating/mounting, progression from initial tread cut/chip/road hazard injury or chemical contamination. Surface texture may have initially shown abrasion marks from the tyre sliding on the road, but the surface may have since worn smooth.

When the tyres with a flat spot are used in a dual application. you may consider rotating one tyre 180 degrees in relation to the flat spot on the other tyre.

If the tread depth is at or below 1.58 mm (2/32") in any groove or if either cord or under tread is exposed, the tyre must be replaced.

When the cause of the flat spot is not apparent, your tyre dealer should contact our Consumer Care Department.

Feathering is a condition when the edge of each tread rib develops a slightly rounded edge on one side and a sharp edge on the other. The most common causes of feathering are incorrect toe-in setting or deteriorated bushings in the front suspension. The toe setting should be as close to 0 as possible for the optimum wear.

The tyres should be inflated to the pressure as indicated on the sticker on the inside of the driver’s door. The vehicle manufacturer has determined this pressure is optimal for load, ride, handling, rolling resistance and tread-wear performance.

The brownish color on the sidewall of your tyres is not a defect. The source of this discoloration can be varied. One possibility is that the tyres contain an anti-ozone agent in their rubber compounds to slow down the ill effects of exposure to ozone in the air. This anti-ozone ingredient will migrate to the surface of the rubber and leave the appearance of a brownish dust. This is completely normal and technically is no cause for concern. In time, depending on usage, it will disappear.

Other possibilities for discoloration can be simply dust that is picked up from normal driving or brake dust which is generated by the abrasion of the brake pads against the brake rotor. This latter condition is more prevalent when the brakes are new or have recently been relined. In all cases, we recommend that you continue to clean your tyres with mild soap and water.

Tread-wear or life

expectancy is determined by many factors:

Driving habits and style of driving, geographical location, type of vehicle,

type of tyre, how the vehicle is maintained and how tyres are maintained, etc.

As a result, mileage expectancy is impossible to determine.

Our Limited Warranty covers defects in workmanship and material for the life of the tread or six years from the original date of purchase, whichever occurs first. We offer no mileage warranty on the tyres that were originally equipped on your vehicle.

We suggest that you have the tyres/vehicle inspected by a participating tyre retailer in your area to determine if there is perhaps a mechanical or maintenance issue that could be contributing to a rapid or irregular wear pattern.

Your satisfaction is important to us. Please have the dealer contact us with the tyre inspection as we are willing to offer you assistance with your concern

The condition, sometimes referred to as sidewall undulations, is a common characteristic of radial tyre construction is are purely a visual characteristic and will not affect the performance of the tyre. These indentations are more noticeable in larger/wider radial-ply tyre sizes and become more visible with higher inflation pressures. The joining of the ply material in the sidewall area may cause a slight indentation or wavy appearance on the sidewall surface of the tyre when it is inflated. However, if bulges, rather than indentations appear on the sidewall of the tyre, or if there is any question concerning any sidewall indentations, please contact a tyre dealer for a tyre inspection.

Noise is most commonly due to an uneven or irregular wear pattern that has developed on the tyres.

A separation between the tread rubber and the underlying belt may be the result of cumulative poor inflation maintenance, improper inflation pressure, repair or storage, excessive load, speed or heat, prior impact damage, tread cut or puncture or being run flat.

A tyre exhibiting this condition should be permanently removed from service.

The tyre industry refers to tyres in this condition as "run flat" which refers to a tyre that has lost air, whether it is from a slow loss or an immediate loss, and then subsequently driven on. As the tyre continues to operate or "run" with a significant amount of air loss, it reaches the "run-flat" stage, where serious internal damage is caused by the excessive deflection of the casing. If the air loss continues, the inside of the deflected sidewall can actually rub against itself. When the internal abrasion weakens the casing sufficiently a blowout can occur. Additional damage is often done by the relatively sharp rim flange cutting into the fully deflated casing as it is driven after the blow out, even in the short distance it takes to drive the vehicle to the side of the road.

We are not indicating that the tyre was not maintained, but simply that it lost air. Some of the many factors which can cause a tyre to lose its inflated air pressure are penetrations, cuts, snags, impact breaks, valve stem leaks and incorrect mounting, just to name a few. While it may not be possible to pinpoint the cause of initial air loss, we know the outcome is under-inflation damage

The life of a tyre cannot be measured by miles alone. Tyres are composed of various types of material and rubber compounds, having performance properties essential to the proper functioning of the tyre itself. These component properties evolve over time. For each tyre, this evolution depends upon many factors such as weather, storage conditions and conditions of use (load, speed, inflation pressure and maintenance etc.) to which the tyre is subjected throughout its life. This service-related evolution varies widely so that accurately predicting the serviceable life of any specific tyre in advance is not possible.

It is impossible to predict when tyres should be replaced based on their calendar age alone. However, the older a tyre the greater the chance that it will need to be replaced due to the service-related evolution or other conditions found upon inspection or detected during use.

While most tyres will need replacement before they achieve 10 years, it is recommended that any tyres in service for 10 years or more from the date of manufacture, including spare tyres, be replaced with new tyres as a simple precaution even if such tyres appear serviceable and even if they have not reached the legal wear limit.

The warranty covers defect in workmanship and material for the life of the tread or six years from the date of purchase, whichever occurs first. With no proof of purchase, the warranty period is for six years from the date of manufacture (this is indicated in the DOT number on the sidewall).

Cupping can be attributed to bent or worn suspension parts, wheel misalignment and an imbalance of the tyre/wheel assembly, etc. Once this type of wear pattern has occurred, it is irreversible and the tyres will continue to wear unevenly.

Vibration is an indication that your car has a problem that needs attention. The tyres, steering system and suspension system should be checked to help determine the possible cause and correction of the vibration. If left unattended, the vibration could cause excessive tyre and suspension wear. It could even be dangerous.

Factors that can affect rapid tyre life are:

- tyre maintenance (inflation and rotation)

- vehicle maintenance (alignment and suspension)

- driving styles and habits

- materials used in road surfaces

- topography of the area the vehicle is driven in.

Incorrect alignment settings can adversely affect handling. Tolerable camber, caster and toe settings can be verified by a print-out from your alignment/tyre shop or vehicle dealer.

If the tyres are evenly worn, the alignment is in order and there is still a pull, the front tyres should be crisscrossed (as long as they are not a directional tread design) to see if the pull changes directions.

Cord material may become

visible at the base of tread grooves or slots due to under-inflation,

misalignment, loose/worn suspension components, hard cornering, improper tyre

rotation practices, misapplication, high crown road or non-uniform mounting.

Адрес:Комната 0803, Пляж Особняк 1,No.230 Шэньчжэнь Роуд, район Лаошань, Циндао, Китай, 266101

E-mail:info@hanstyre.com

Вебсайт: www.hanstyre.com